Clarifying the Serbia Data in Highway’s 2025 Freight Fraud Report

Last week, Highway released its Q4 2025 Freight Fraud Trends Report. The report outlined the countries outside the U.S.

Why most freight AI projects won’t survive 2026. Learn the automation risks teams face and how reliable, scalable workflows prevent failure.

Every time a new AI model is released, the hype cycle starts over. Bold claims flood LinkedIn: “AI-first companies.” “Fully automated operations.” Templates that promise overnight transformation.

But as 2025 comes to a close, most logistics teams aren’t asking which model is best anymore. They’re asking a harder question:

What automation will actually hold up in 2026?

After several years of pilots, experiments, and proofs of concept, the freight market is entering a more pragmatic phase. Budgets are tighter. Headcount is leaner. Leadership teams are under pressure to do more with the same or less. And tolerance for hype-driven initiatives that never reach production is wearing thin.

This shift is changing how companies think about AI. The focus is moving away from experimentation and toward operational readiness.

That’s where Levity positions itself, not as another AI tool, but as a 2026 readiness partner for freight operations.

Despite the noise, AI adoption in logistics remains uneven. Many initiatives stall after early demos, while others deliver isolated wins but fail to scale across teams, regions, or customers.

That unevenness shows up clearly in how freight teams see the road ahead.

In a recent FreightCaviar poll asking where teams expect their AI maturity to be in 2026, the majority of respondents said they would still be experimenting or just getting started, with fewer expecting AI to be fully integrated into daily workflows.

That gap points to an execution problem, not a lack of interest. Many teams want AI to work, but aren’t confident that their current tools, processes, or data are ready to support it at scale.

When AI does deliver value in freight, it rarely comes from moonshot visions of full autonomy. Instead, it shows up through small, repeatable improvements:

In other words, the unglamorous, high-friction work that keeps freight moving every day.

Levity’s founders have been consistent about this reality. Publicly, they’ve pushed back on the idea that the next breakthrough will come from ever-larger models. The real opportunity sits in the application layer and how AI is embedded into real workflows, with guardrails, integrations, and accountability.

Because automation that looks impressive in a demo is very different from automation that survives production, scale, and edge cases.

Most freight companies underestimate how much operational work lives inside the inbox.

Quote requests. Load tenders. Tracking updates. Appointment changes. Invoice follow-ups. Multilingual emails with attachments, screenshots, or partial information. This is the true workflow.

Yet heading into 2026, many teams still don’t know:

Automating without this visibility is risky.

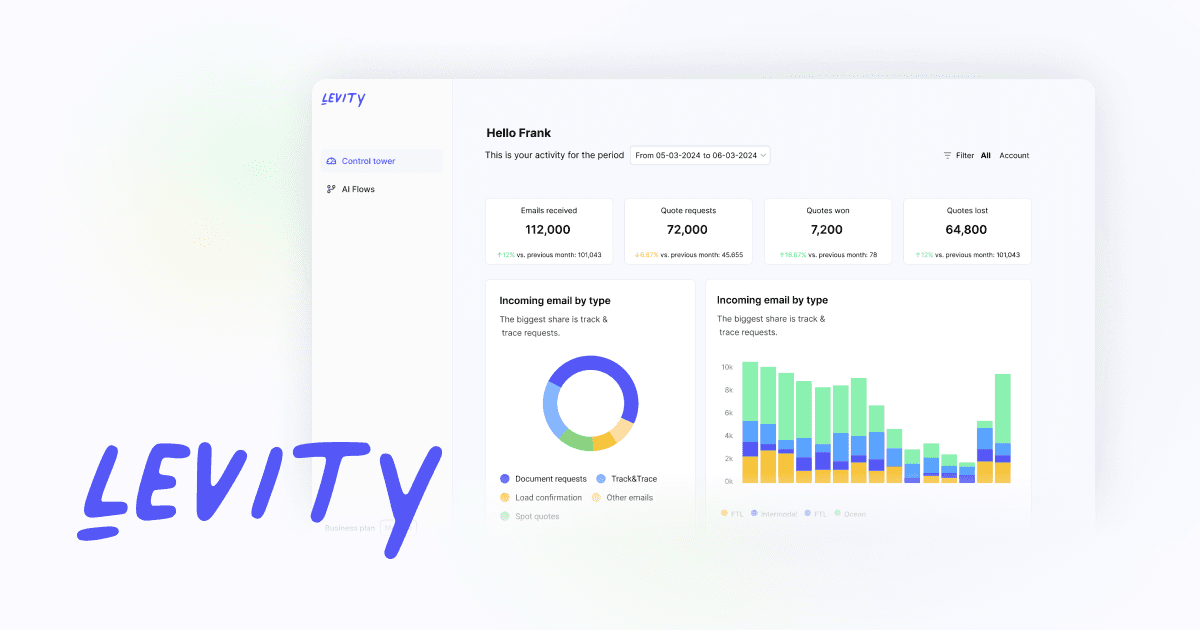

Levity starts here by design. Instead of automating blindly, Control Tower gives freight teams a clear picture of their email-driven operations first, breaking down volume by request type, tracking response times, and surfacing bottlenecks that quietly erode margins and service quality.

In 2026, visibility is a prerequisite for responsible automation.

Experimenting with AI is easy. Relying on it every day is not.

Freight workflows are inherently messy. Emails arrive incomplete. Instructions vary by customer. Attachments change formats. Language shifts across regions. Edge cases pile up quickly.

This is where many automation initiatives fail because AI isn’t designed for this level of variance.

Levity is built around a principle the team calls Reliability by Design.

With AI Flows, automation is not left to a black box. Teams combine AI reasoning with rules, thresholds, and fallback logic to create hybrid workflows. AI handles the heavy lifting, while humans stay in the loop when confidence drops or exceptions arise.

This approach matters as companies plan for 2026. Fragile automation may look impressive early on, but it rarely survives scale. Reliable automation—designed to handle variance—is what compounds over time.

Another reality of 2026: most freight companies are not ripping out their existing tech stack.

Legacy TMS platforms, CRMs, shared inboxes, and internal tools aren’t going away overnight. AI initiatives that require full system replacements or massive IT overhauls often stall before they ever deliver ROI.

Levity is designed for that reality.

The platform integrates directly with email, TMS, CRMs, and more than 5,000 tools directly via API. Automation happens where the data already lives without brittle workarounds or forced process rewrites.

This lowers risk, shortens time to value, and makes AI automation a practical investment, not a multi-year transformation project.

For companies heading into 2026 with cautious budgets and high expectations, this is key.

In 2026, “we’re testing AI” won’t be enough.

Leadership teams will expect clear answers:

This is where many AI initiatives fall apart. Without measurement, automation becomes anecdotal. Wins are assumed. Failures go unnoticed.

Control Tower closes that loop.

It tracks automation performance in real time, monitoring request volumes, response speeds, SLA risk, win/loss ratios, and even customer sentiment. Instead of waiting for monthly reports, teams can adjust workflows continuously.

Compliance pressures are also changing what leadership expects from automation.

After a year marked by increased fraud exposure and regulatory scrutiny, being fast isn’t enough. Teams need to show how decisions were made, where exceptions occurred, and when human review was triggered.

That’s why measurement and auditability are becoming non-negotiable in 2026.

Levity isn’t betting on the next model release.

It’s betting on the application layer where AI meets real workflows, real systems, and real accountability. That focus shows up across its platform, from inbox visibility and hybrid workflows to seamless integrations and enterprise-grade security.

As freight companies prepare for 2026, the competitive gap won’t be between those who “use AI” and those who don’t. It will be between teams that embedded automation into daily operations and those still experimenting at the edges.

Levity helps companies make that shift now, starting where the work already happens.

Not by chasing models. But by automating work.

Contact Levity today.

Join over 14K+ subscribers to get the latest freight news and entertainment directly in your inbox for free. Subscribe & be sure to check your inbox to confirm (and your spam folder just in case).